ANUBIS

Building the knowledge for better dismantling

As part of the Belgian plan for EU’s post-pandemic recovery, SCK CEN has submitted a project linked to the sustainable dismantling of the Belgian nuclear power plants. ANUBIS, as it was dubbed, stands for Advancing NUclear dismantling in Belgium through Improving Sustainability. A nice way to say that we’re building a research, development and demonstration (RD&D) facility and accompanying installations to support innovation of decommissioning practices in Belgium.

Not only does this fit the EU’s ambitions for a sustainable and digital transition, it also means industrial players can take advantage of the economic opportunities.

Interested to apply your technology for dismantling operations? Do not let your chance go by, let us find your new breakthrough together!

Closing knowledge and technology gaps

Our number one goal is to develop the necessary technologies and competences to maximize the reuse and recycling of materials coming from future decommissioning operations of the Belgian nuclear power plants in a cost-efficient way. That is why additional research is needed to close certain knowledge gaps, and advance our technologies to present-day sustainable standards.

Sustainable dismantling of large material streams

Dismantling a nuclear power plant involves the management of a lot of material streams. Now imagine dismantling 5 of them in parallel. So we’re further exploring our best practices to streamline operations, minimize radioactive waste and maximize the amount of material that can be safely released without radiation risks. Of course, all according to local legislation and procedure standards.

ANUBIS aims to deliver approved methodologies for characterization, treatment, decontamination and conditioning, ready to use during the dismantling of the Belgian NPPs.

The dismantling of Belgium’s prototype pressurized water reactor BR3 is seen as an international reference. Thanks to SCK CEN’s pioneering work on dismantling BR3, we were able to grow our expertise and share these insights on an international level.

Using innovative digital technologies

To handle the thousands of tons of material streams that come with dismantling a nuclear power plant, you need a close follow-up.

So, we’re upgrading all material inventory and tracking systems to the newest IT standards and investigate how novel technologies such as automation technology, artificial intelligence (AI), machine learning (ML) and building information modelling (BIM) can help decommissioning operations! Pretty cool, right?

These innovative digital technologies are used for enhanced material handling, such as material characterization, but also to build a next level material data management system that includes a strategy decision tool or to implement a more accurate radiological protection of the workers during dismantling activities.

Upscaling toward industrialization and stimulating innovation

In a second stage, we are looking at scaling opportunities for industrial applications in nuclear technology. In line with the EU’s objectives for the recovery and resilience fund, this brings advantages in terms of industry growth, local expertise and innovation strength.

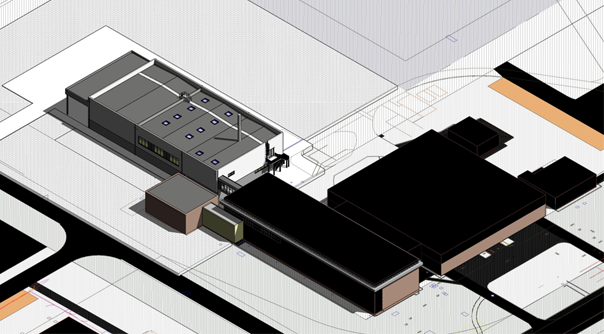

An innovation hub for decommissioning technology development

Our new material treatment facility, where all our new RD&D installations related to decommissioning will be located, is also open for 3rd parties as of 2025. Here, you will be able to:

- investigate your products in hot (nuclear) and cold (non-nuclear) areas

- validate your technology for nuclear applications

- maintain or repair contaminated equipment

Given the presence of both SCK CEN’s experts as well as specialized companies actively developing D&D technology, this facility will become a true Belgian innovation hub. Do not miss out!

Close interaction with industry stakeholders

It would be a shame to build this sanctum of nuclear know-how and not open its doors for like-minded industry players. That is why SCK CEN is organizing stakeholder events to have project updates and opportunities to exchange ideas. Moreover, we’re joining forces with industrial companies for specific R&D collaborations.

By working together we hope to enable a sustainable, safe and cost-efficient dismantling process.

RD&D updates

-

New industrial partnership: MAGICS

4th collaboration in ANUBIS project focuses on global, industrial applicability of waste management.

-

3D radiation dosimetry - ALARA planning tool

SCK CEN is currently developing and testing an ALARA dosimetry tool with VR integration.

-

3 partnerships focussing on radiological characterization

3 industrial partners - Mirion, Ludlum and SYSCADE - are each joining forces with the Belgian Nuclear Research Centre.