Nuclear melting furnace also receives green light from Europe

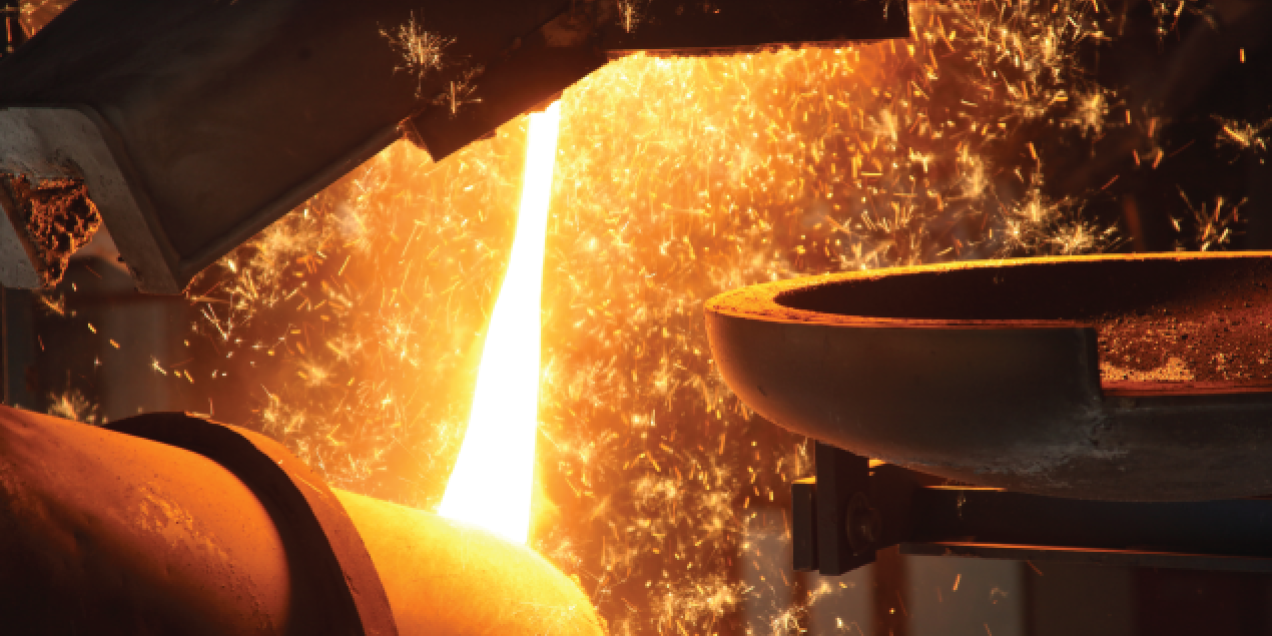

SCK CEN and CRM Group boost the circular economy in dismantling by constructing a nuclear furnace

The European Commission has given the final go-ahead for the development of the Belgian melting furnace for research purposes. The furnace will encourage the creation of a circular economy in nuclear dismantling, by enabling larger quantities of metal to be given a second life than can possibly be achieved using the melting technologies currently available. As the nuclear research centre SCK CEN and the Centre for Metallurgical Research (CRM Group) jointly stated, “This decision by the European Union reconfirms the social importance of our plan.”

Let us wind things back a little. The nuclear melting furnace for research purposes – known as SMELD – is a project being undertaken by the nuclear research centre SCK CEN and the Liège-based research institution known as the Centre for Metallurgical Research (CRM Group). The two project partners intend to complete the work to construct the furnace by 2026. After the Belgian government previously committed itself to invest 13.5 million euros in the project, it has now also received the blessing of the EU.

Thomas Dermine, Secretary of State for Recovery and Strategic Investments, underscores the significance of this recognition: "The approval from the European Commission for the nuclear melting furnace SMELD is a powerful example of how Belgium, with European support, takes a leading role in developing new technologies with global potential. The SMELD project illustrates the targeted allocation of resources to promote a circular economy in dismantling, demonstrating that with innovative approaches, we can reduce the ecological impact of nuclear dismantling. It is a tangible result of our commitment to sustainability and technological advancement."

SCK CEN and CRM Group, both partners in the project, are thrilled about this news. “In Europe, more than 70 nuclear reactors have already closed down and it is estimated that dozens more will follow in the coming years. It therefore won't be long before they fall due for dismantling. Recycling and re-using the maximum quantity of materials makes it possible to reduce the ecological footprint of dismantling. And that is what this project is all about: a desire to create a circular economy in dismantling,” responded Guido Mulier, a dismantling expert at SCK CEN.

Recycling more

By implementing this project, SCK CEN and the Centre for Metallurgical Research (CRM Group) have set themselves the target of developing a facility that will enable larger quantities of metal emanating from dismantling to be recycled. They are focusing their attention on material that is too radioactive to be recycled immediately, but not radioactive enough to be disposed of as radioactive waste. “That particular category actually accounts for considerable volumes. We believe that by putting in place the right technologies and installations, we will be able to give that metal a second life,” explained Joeri Neutjens, CEO of CRM Group.

An advanced melting furnace

The intention is that SMELD will lead to an upgraded form of the technology being used in today's large-scale melting plants. By capturing most of the radioisotopes during melting and separating them from the metal, they are already bringing about a dramatic reduction in the quantity of radioactive waste. Nevertheless, some radioisotopes are difficult to ‘capture’ using the techniques currently available. “We – literally – believe that still more can be got out of the process and have made it our target to ensure that the new melting furnace is more effective at isolating those residual radioisotopes as well Larger quantities of metal can then be recycled and re-used,” continued Joeri Neutjens (CRM Group).

Feasibility study

“That is certainly our ambition, but we must first await the results of our fundamental research and our feasibility study,” said the two project partners, as if to temper the expectations. These should provide answers to various questions such as “How do those radioisotopes behave before, during and after the melting process?”, “What can we do to improve existing industrial techniques in order to meet our specific requirements?” and “Is the furnace also suitable for material originating from other nuclear facilities, including cyclotrons?”

The furnace will undergo an extensive development process, in which advanced thermodynamic simulations will be combined with laboratory-scale provisional feasibility and optimisation tests. The initial part of that process is being carried out at CRM Group using non-radioactive materials and will be followed by small-scale tests at SCK CEN using radioisotopes. The two project partners will then scale up the development into a genuine, advanced processing furnace. They are set to deliver this in 2026.

What exactly does the development project involve?

-

We make use of mathematical models and analyses to simulate the behaviour of the furnace. The intention behind this is to obtain an in-depth insight into how the furnace responds to different conditions, such as temperature fluctuations, pressure variations, energy efficiency, melting behaviour… In short, these simulations will help researchers utilise and optimise the thermal and chemical processes thought to take place inside the melting furnace itself.

-

We use this to validate theoretical insights obtained from the simulations and to improve the performance of the furnace. This is our way of testing the practical feasibility of the melting process, including the way in which the furnace operates and the materials are processed and the interaction with the radioactive metal itself. These provisional tests will enable researchers to identify potential optimisations and address any unexpected challenges before the system becomes fully operational.

-

The development process comprises a systematic approach, commencing with simulations and tests on a cold scale (without radioisotopes) in the laboratories at CRM Group. Once the initial phases have been completed successfully, the process will continue in the form of ‘hot tests’ (with radioisotopes) at SCK CEN. These too will initially be carried out on a laboratory scale using table-top versions of the furnace. If the effectiveness and safety of the furnace can be ensured, we will then carry out testing on a larger scale at SCK CEN.

A boost to the economy

The advent of an advanced processing furnace represents a trump card that will enable Belgium to put itself on the international map. “Any country commencing a dismantling project stands to benefit from improved recycling techniques. We are paving the way towards an installation of that type, the commercial operation of which will ultimately be undertaken by an industrial partner. SCK CEN and CRM will reserve the right to continue carrying out research in that installation as a means of optimising existing techniques, but also new ones” concluded Guido Mulier (SCK CEN).

SMELD in a nutshell

SMELD stands for State-of-the-art MEtal MElting Limiting waste during D&D. The project being carried out by the nuclear research centre SCK CEN and the Liège-based research institution CRM Group aims to provide an advanced nuclear melting furnace for research purposes. Under the Belgian Recovery and Resilience Plan coordinated by State Secretary Thomas Dermine, Belgium's Deputy Prime Minister Dermagne and Minister Van der Straeten are making available a sum of 13.5 million euros for this infrastructure. By developing this furnace, the project partners are contributing towards the development of the circular economy, while at the same time creating an export product for Belgian industrial players.

"This state-of-the-art furnace will eventually enable us to recycle the steel from our nuclear power plants, which has a limited level of radioactivity, while giving new impetus to Belgium's leading expertise in innovative nuclear technologies. This major investment will bring sustainable economic development and local jobs in the key decommissioning sector", adds Pierre-Yves Dermagne, Deputy Prime Minister and Minister of the Economy and Employment.

Related articles

23 April '24

23 April '24 29 February '24

29 February '24 07 December '23

07 December '23