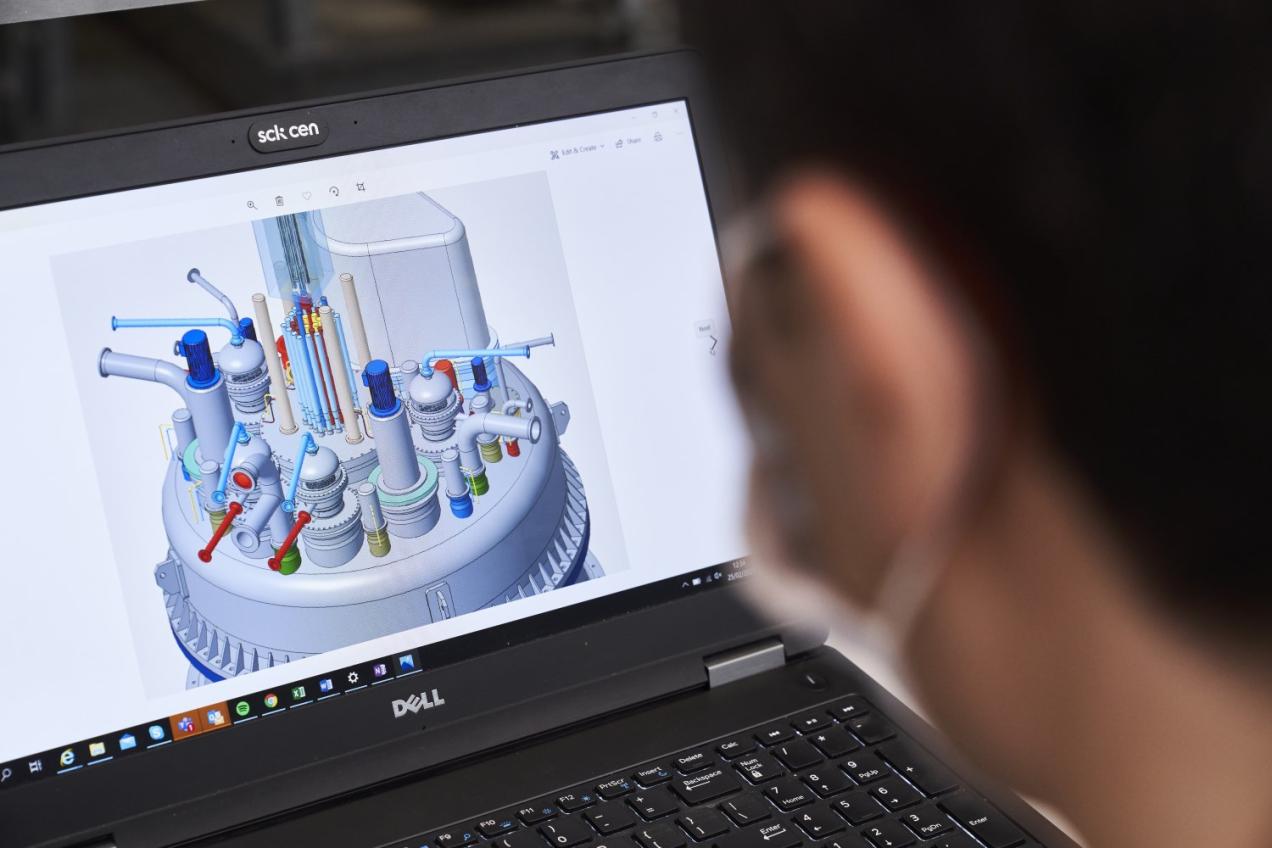

MYRRHA reactor vessel slims down

Renewed design combines safety and economic feasibility

Four metres shorter and two metres narrower. The renewed design of the MYRRHA research reactor is not only smaller, but also more economical and significantly safer. The message: “This revision brings us another step closer to the realisation of MYRRHA.”

Good science takes time: time to make considerations, to let ideas take root and to conduct thorough tests. Sometimes, scientists and engineers must adapt a concept and then repeat the qualification testing. This is all the more true when they are moving into unexplored territory. Rafaël Fernandez knows this too. This engineer at SCK CEN and his team are drawing up the design of MYRRHA, the world's first research reactor driven by a particle accelerator. The core will not be cooled with water, but with a liquid metal. “Lead-bismuth,” Fernandez clarifies. “An innovative installation requires innovative materials. We have to be sure that every material used or component chosen in our reactor design can handle the conditions of the research reactor without problems. We have an extensive R&D program to test every design aspect in practice: from safety to economic feasibility and even logistics. We use that knowledge to systematically adjust our design.”

Last year, the engineers completed revision 1.8. This design provides an answer to all the safety requirements and points for improvement, as identified by the research programme in revision 1.6. “The coming year should conclusively answer the question of whether the final design is now on the table. We will subject the new components to extensive testing,” says fellow engineer Graham Kennedy. A final design is therefore in sight.

Far-reaching improvements

What changes did the researchers actually make? “First and foremost, we made the reactor vessel slimmer. In height it shrank by about four metres, in diameter by almost two metres. This modification was necessary in order to be able to transport the reactor vessel in its entirety from the manufacturer to SCK CEN,” says engineer Graham Kennedy. “It takes 200 cubic metres less of lead-bismuth to fill the reactor vessel, a substantial saving.”

The challenge was to reconcile that downsizing with the safety requirements. The engineers had to fit larger heat exchangers into a smaller reactor vessel to compensate for a less efficient heat transfer process. Rafaël Fernanadez explains: “The lead-bismuth transfers its heat to the water that flows through the heat exchanger tubes. In this design, the tubes are double walled. That double wall is an additional safety mechanism that we've built in. It should prevent the water and lead-bismuth from mixing in the event of a rupture and causing certain radioactive products to evaporate through that reaction. A double wall reduces heat transfer. This is precisely the reason why we install double-glazed windows in houses, but in the MYRRHA research reactor, we want to cool things down instead of retain heat.”

Safety

The engineers managed to put together the complicated puzzle. “The input from colleagues who each have a different background and who looked at the issue through different lenses is what helped us succeed. More than that, we were able to combine the best of both worlds. By modifying the design, we significantly improved safety and were able to reduce costs. And sometimes we had to drop old concepts. For example, we went from two fuel handling machines to one, and were able to reduce thermal stresses by modifying the diaphragm design. The diaphragm is a partition that separates the relatively cold high-pressure lead-bismuth from the hot low-pressure refrigerant.” In the next step, the engineers will link the reactor vessel design to the secondary and auxiliary systems.

Scaling the highest heights

The best view comes after the toughest climb – a statement that is familiar to any mountaineer and is also true for ambitious projects such as MYRRHA. Such innovative installations require a more extensive R&D programme in the development phase, but they offer a genuinely positive outlook. More than that, they are the key to tackling societal challenges. I offer my congratulations to the team that is designing this unique 'key' and is realising the construction of MYRRHA.

Hamid Aït Abderrahim

Deputy Director General and Director of MYRRHA

Key figures