SCK CEN ensures safety of nuclear innovations

SCK CEN installation puts fuel rods to the test

SCK CEN has been testing newly developed nuclear fuel rods as far back as 1976. These tests are the final part of a new fuel’s safety file. Last year, the research centre replaced its installation, which it is now using to carry out these tests – the only one of its kind in Europe. "What was supposed to be a copy of the previous version became an installation with more features and more measurement instrumentation," says project manager Brian Boer.

A car hitting a lamppost, overturning or colliding head-on: no model of car is permitted to come to market without passing a crash test. "A crash test evaluates the impact of an accident and therefore the safety. The equivalent for nuclear fuels is the transient test," says Marc Verwerft, nuclear fuel expert at SCK CEN. A transient test simulates a sudden power increase in a reactor. The aim is to test what power increase will cause the cladding – the first physical barrier of the uranium fuel – to fail.

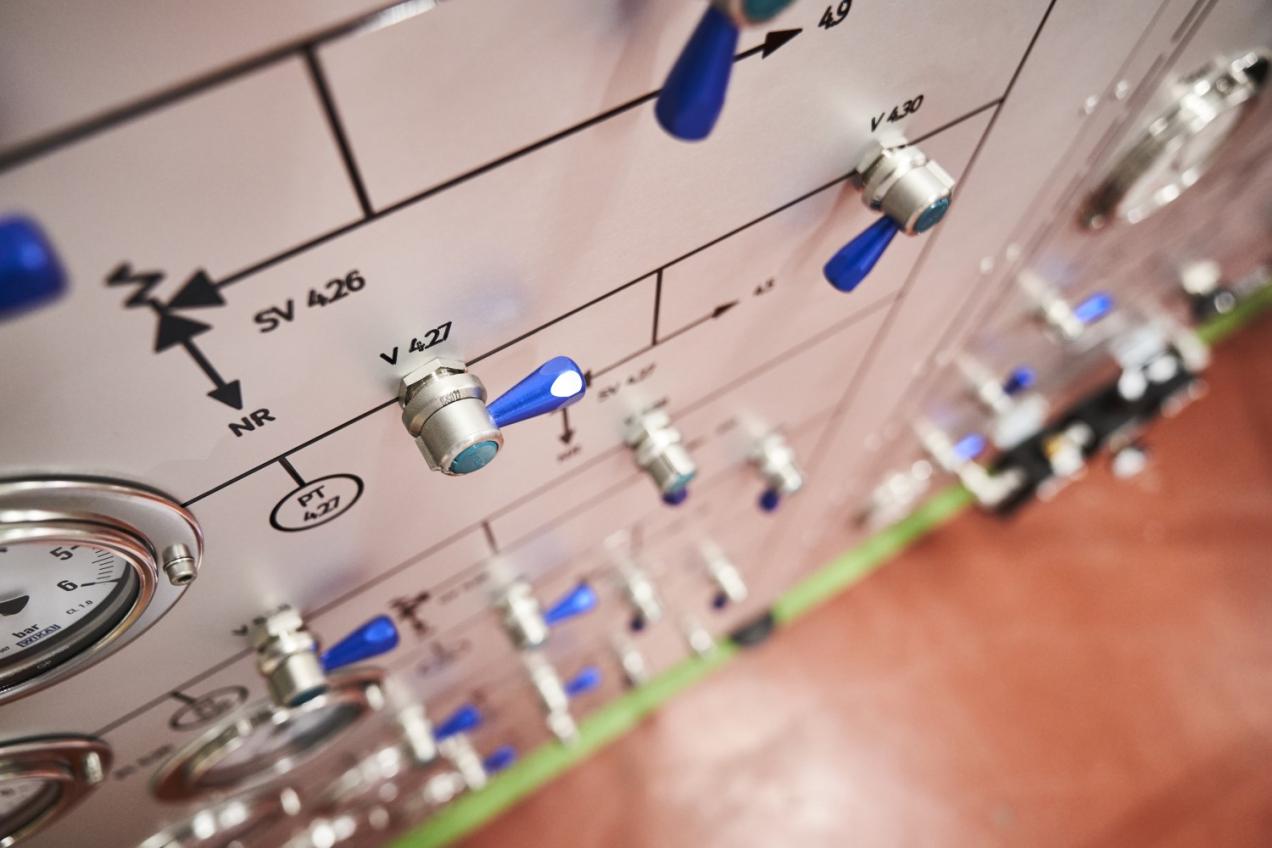

Transient tests are essential for ensuring the safety of nuclear power plants. The BR2 research reactor at SCK CEN is the only one in Europe that is capable of performing such necessary tests. "We've been providing this service since 1976, but recently we commissioned an upgraded facility," Verwerft explains. That installation is called PWC7. PWC stands for Pressurised Water Capsule, while the number indicates it is the seventh generation of it. "What was supposed to be a copy of the previous version became an installation with more features and more measurement instrumentation," says project manager Brian Boer.

Highest accuracy

The measurement instrumentation allows more factors to be mapped: What is the water temperature in the capsule in which the researchers placed the fuel pin? How hot does the fuel cladding get? How does the pin expand during irradiation? Does the diameter of the cladding change? What neutron and gamma flux are we obtaining? What internal pressure is exerted on the fuel pin? All of these things are determined with the highest accuracy. Marc Verwerft explains: "In order to confirm our repeatability and accuracy, we have performed numerous qualification tests over the past two years: both with dummy fuel pins and with real fuel rods. The upgraded installation meets all high quality and safety requirements. So it's is ready for the next step: the first commercial, nuclear transient test. That's scheduled for the second half of 2021."

Test procedure

Then comes the question: what happens in a transient test? How does SCK CEN imitate a commercial nuclear power plant 'going through its transient'? The fuel pins the research centre receives have been previously irradiated for several years under normal conditions. Fuel pins in a commercial power plant are four-metre long tubes into which uranium fuel is stacked in the form of ceramic pellets – cylindrical tablets about 1 cm high. "For our transient test, we take a half-metre-long sample, load it into a PWC water capsule, and position it in the reactor core of BR2," says Brian Boer.

This position has been accurately calculated to simulate an accident. The reactor runs at low power for a day, after which the reactor operators double the power in under two minutes. This increase causes the temperature of the test pin to rise. The outside temperature remains at the normal operating temperature, but in the fuel core the temperature doubles to well over 2000 °C. As the temperature rises, the fuel expands and exerts pressure on the cladding. "If we see activity in the water of the PWC, then the cladding has failed; the test is stopped and the damage examined. If there's no activity, we maintain that power for twelve hours and then examine the pin for damage. This could be small cracks that you can't see with the naked eye, for example."

The results generated by the transient test are used to validate computer codes, which can then be used to perform dozens or hundreds of simulations. "A transient test pushes the safety margins of nuclear fuel and forms the final part of a licence dossier. With our experiments, we enable the industry to introduce innovations in a safe way," concludes project manager Brian Boer.

Increased capacity

The PWC7 can – in addition to the transient test – also be used for other purposes. First, customers can ask us to look at how fissile materials react when nuclear power plants respond more to energy peaks and troughs and when power output fluctuates more frequently. Second, they can ask us to test burnup limits, and third, they can put new materials to the test. SCK CEN is already considering a PWC8 and PWC9 to increase capacity.

SCK CEN adds a new dimension to nuclear research

Impactful science is shaped by, and for, people