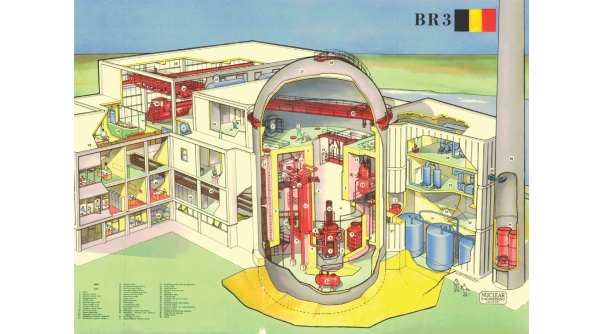

BR3 - Belgian Reactor 3

An example to the world

The 1st pressurised water reactor in Europe & 1e decommissioning project

The Belgian Reactor 3 was the first pressurised water reactor in Europe. It was taken into service in 1962 and shutdown for good in 1987. The reactor served as a prototype for the reactors in Doel and Tihange. The European Commission selected BR3 as a pilot project to show the technical and economic feasibility of the dismantling of a reactor under real conditions.

At this moment, the project is in its last stage: restoring the site in its original state. SCK CEN disseminates the expertise that it has developed with the decommissioning of BR3 both on a national and international level. These valuable insights are also an excellent guideline for the design of new nuclear plants.

The decommissioning of BR3

BR3 was shut down in 1987 and is the very first reactor to be dismantled on a large scale. Dismantling has been underway for 35 years and is almost complete.

Today, the decommissioning of BR3 is the basis for the decommissioning plan of the Doel and Tihange nuclear power plants in Belgium.

How do you reduce and sort nuclear waste?

One of the biggest challenges in the nuclear world? Minimising the amount of nuclear waste. After years of pioneering work in BR3, we proudly state that we at SCK CEN have developed extensive expertise for this issue.

Some examples of the sustainable decommissioning of BR3

-

Modelling in 3D

We count on a lot of digital applications to make decommissioning work as safe and as sustainable as possible. Take BR3's biological shield, for example. It is the "shell" around the reactor vessel made of tonnes of reinforced concrete. The shield of BR3 is 15 m high and has a thickness of 1.20 m. That is enough for 2,200 metric tonnes of reinforced concrete – or the loading capacity of 100 trucks.

Instead of transporting those 100 trucks to landfill in one go, we saw the concrete into traditional waste. SCK CEN developed a 3D model that charts the radioactive values in the concrete down to the decimetre; this shows in blue which concrete can be released - in other words, the quantity of concrete that no longer con-tains any radiation.

-

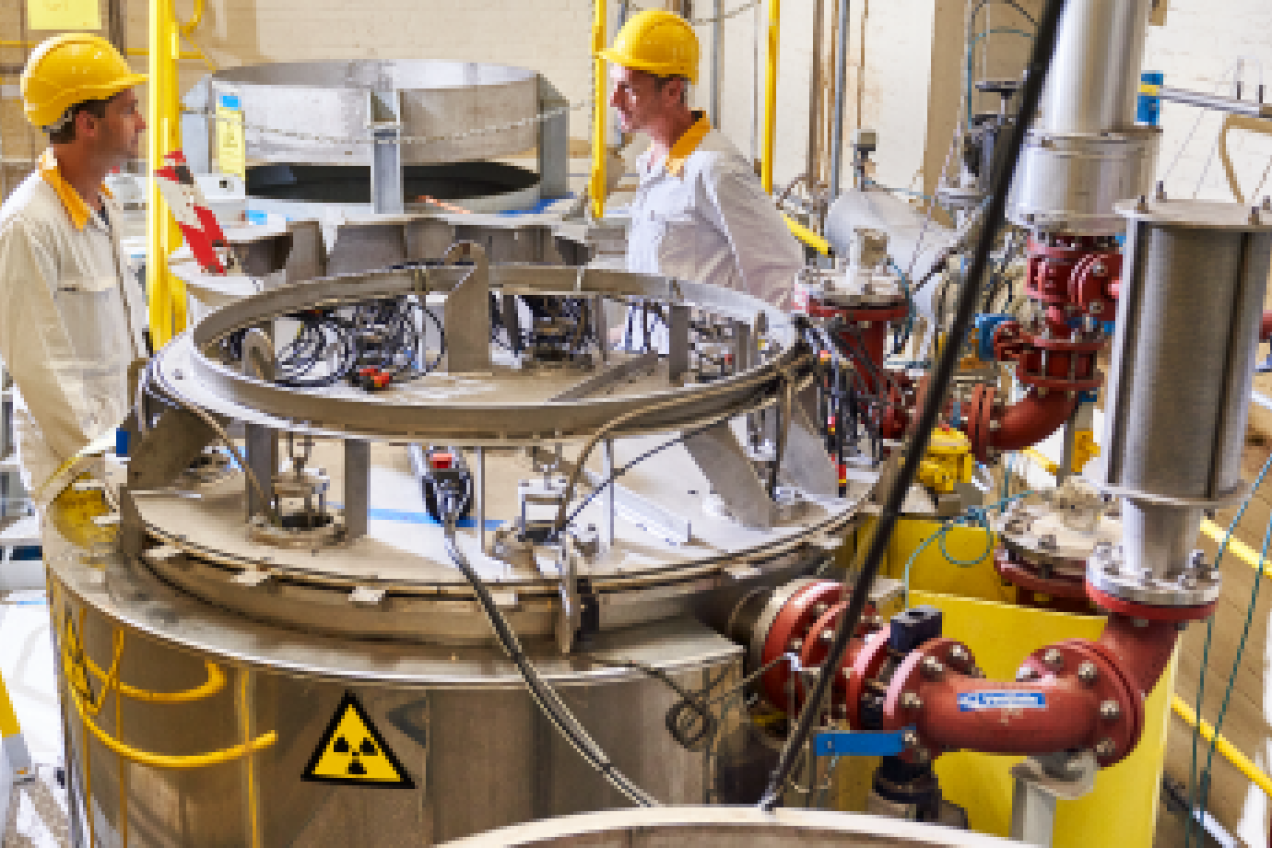

Chemical cleaning

Our experts used various techniques to transform radioactive BR3 pieces into recyclable materials. These included the MEDOC technique, invented and optimised by our own SCK CEN experts. MEDOC is a chemical way of cleaning metals; for BR3 we treated no less than 71 tonnes of metal.

How does MEDOC work?

- You immerse metal radioactive reactor parts in an acidic cerium bath at an elevated temperature;

- Allow the cerium to dissolve the contaminated surface layer so that the metal is free of radioactivity;

- After treatment and a measurement check, you dispose of the material as scrap metal so that it can be recycled in the steel industry.

-

Further research on innovation

We have not extracted much radioactive waste from BR3 - and yet the proportion could be even lower. This requires further scientific research. On the SCK CEN site, we are constructing a new building - the Material Treatment building (MaT) - in which we will accelerate this research, both solo and together with external companies. Together we are creating an innovation hub where sustainability is central.

Testing promising technologies, maintaining and repairing tools used during the dismantling, experimenting in a radiological setting... MaT makes a lot of things possible. The building's construction and many studies are part of the ANUBIS project, funded by Belgium and Europe. ANUBIS is keen to work with industrial partners to close the knowledge and technology gap in the decommissioning sector.

How to decommission a nuclear reactor?

-

Step 1: Permits & preparation

In consultation with various agencies and residents in the surrounding area, agreements are made about the demolition of the nuclear reactor.

-

Step 2: Final shutdown

Before starting the dismantling works, specialists map the site. What values of radioactivity are measured? We speak of the characteristics of the building, its facilities and the site. Afterwards, the reactor vessel and the various circuits are emptied and the fissile material is transferred to the interim storage facilities.

-

Phase 3 : Decommissiong & sorting

The third phase runs over a period of 10 to 20 years. It includes the decommissiong of both nuclear (e.g. reactor vessel and contaminated circuits) and non-nuclear buildings and equipment. The amount of radioactive waste remaining after decomposition is kept to a minimum by sorting and disinfecting all radioactive components to the best of our ability.

-

Phase 4 : Green field

Decontamination and demolition of all buildings is the final stage of a dismantling project. The dismantling experts want to (re)restore the entire site to its original state and restore its 'green field' status. The site can be reused thereafter.

How much waste have we taken out of BR3 until now?

The residues of BR3 went on quite a journey:

- We dismantled the reactor building;

- We reduced the debris as best we could;

- We investigated what could be done with the residues;

- We transported the waste for recovery, recycling or disposal.

In total, we extracted 2,644 tons of materials to be processed from BR3. Our experts were the first in the world to figure out how to decontaminate materials on a large scale. The main goal? Retaining as little radioactive waste as safely as possible. As pioneers, they succeeded in this brilliantly:

- 1,989 tons of materials were able to be released – no radioactive cargo was involved;

- 115 tons of materials were melted down for subsequent recycling in the nuclear sector;

- 287 tons of materials were melted and then released – thanks to our treatment, no further radioactivity was detectable.

In the end, 253 tons of radioactive waste remain. Thus, more than 90% of the entire BR3 can be released, recovered or recycled.

How many materials were dismantled and decontaminated?

-

We extracted 1,060 tons of metal from BR3. Of which:

- 105 tons were cleaned with water jets;

- 71 tons were chemically decontaminated with our MEDOC technology;

- 34 tons of lead were melted.

-

We extracted 1,414 tons of concrete from BR3. From 501 tons of it, we 'scraped' away the nuclear materials so that it could be released and reused without them.

-

Such as wood, stone rubble, lime, etc. Of that, we cleaned 158 tons. Those materials could then be reused or processed as 'classical' waste.

-

These materials did not contain any radioactive substances and could be recycled immediately or treated as 'classical' waste.