Guaranteeing nuclear safety

How do we guarantee the safety of nuclear facilities?

Several European countries, including Belgium, have decided to extend the life of nuclear power plants. Their safe operation is a priority. After some time, the structural materials in nuclear power plants can be altered by the radioactive radiation that is present during the operation. It is important to research these alterations and to be able to predict them accurately.

Material ageing research

SCK CEN uses its knowledge of material aging to accurately predict the lifetime of nuclear reactors. How do radioactive particles interact with materials? This question has played a central role in projects carried out by SCK CEN to ensure the safety of nuclear applications ever since we founded the research centre.

Consequently, we have built up a wealth of knowledge about fissile and irradiated materials. We study the behaviour of materials in radioactive environments and then apply the results of those tests in various sectors, from fission to fusion. How?

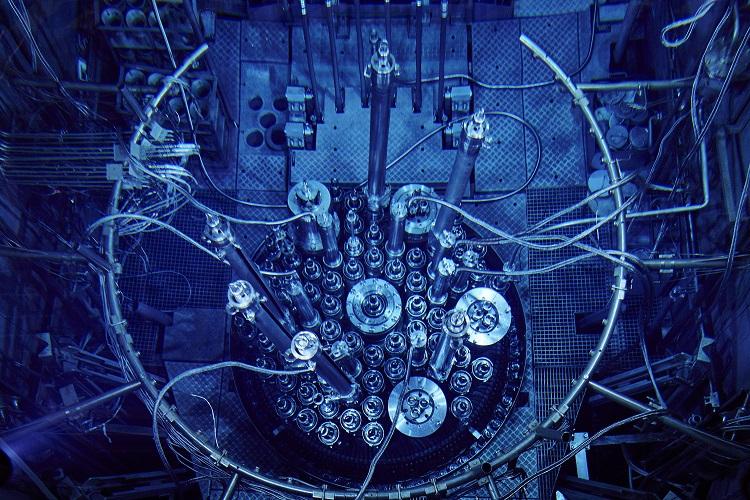

First, we irradiate the materials in the BR2 research reactor, after which our experts in the Laboratory for High and Medium Activity (LHMA) analyse the damage and the aging processes. Those test results are the basis for accurately predicting the lifetime of nuclear reactors. Operators both at home and abroad call upon SCK CEN to advise them on their monitoring programmes.

Irradiating materials

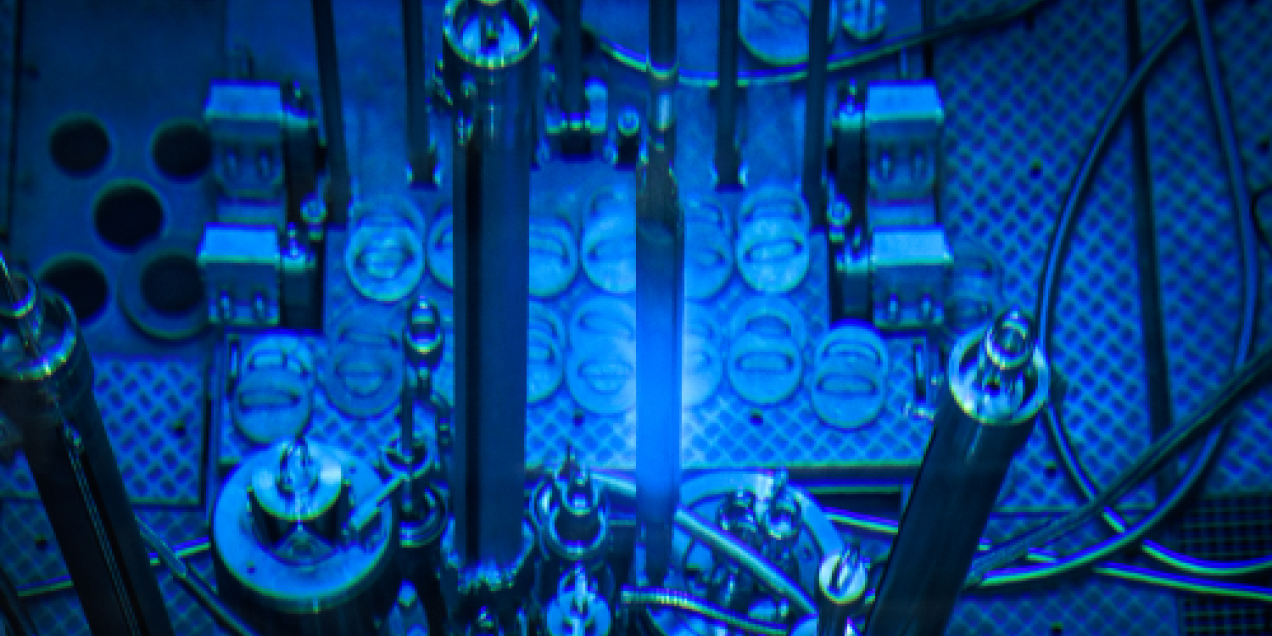

In the materials research, SCK CEN's BR2 research reactor plays an important role. Here, we irradiate all kinds of samples of fissile and structural materials for current nuclear power plants and future reactor concepts. Thanks to the high intensity of the neutron irradiation in BR2, researchers at SCK CEN can accurately predict how materials (will) behave in a nuclear reactor.

In the time capsule

One month in our reactor has the same effect on reactor vessel steel as forty years of ordinary aging in a nuclear reactor. In our reactor we accelerate time, so to speak.

Mechanical and chemical materials tests

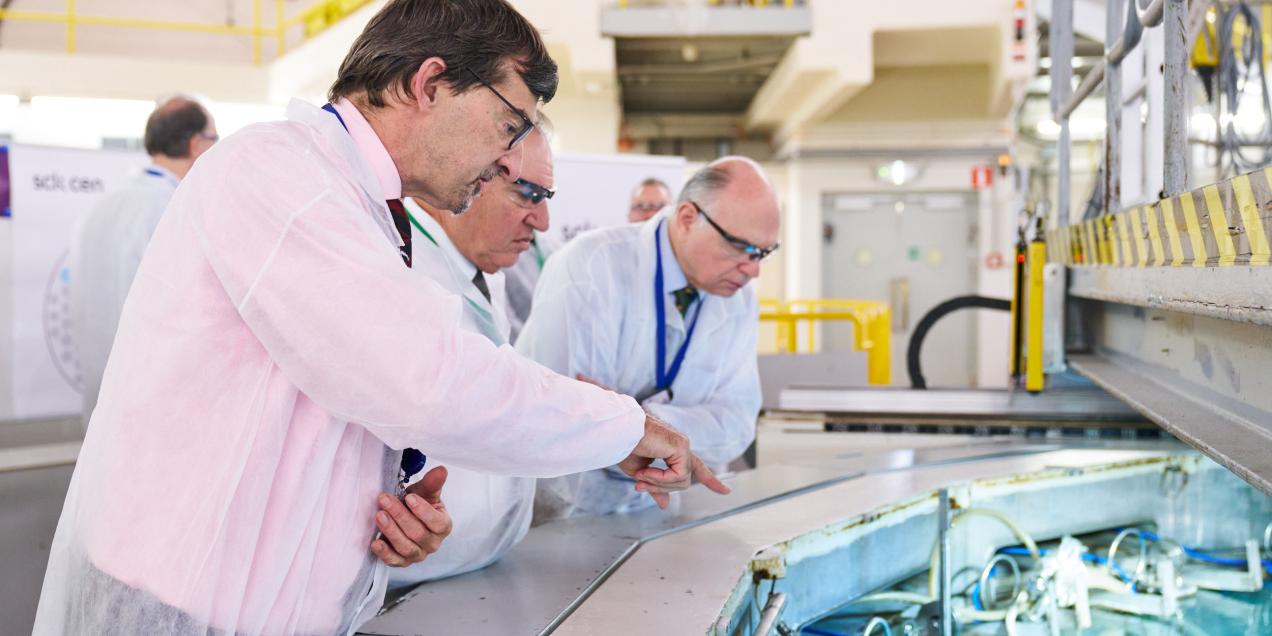

With mechanical, chemical and microstructural research instruments, SCK CEN analyses the damage and aging processes of materials.

One example is the Charpy V-notch test, an international test in which researchers break specimens with a heavy impact hammer to check the fracture toughness of the reactor vessel steel.

Nuclear fusion – the sun on Earth

Nuclear fusion is the technique that mimics the sun's power generation in which two (hydrogen) isotopes collide and fuse into a heavier atomic nucleus (helium). This process takes place under very high pressure and temperature. This means that components in a nuclear fusion reactor are exposed to far more extreme conditions than in traditional nuclear reactors. SCK CEN is investigating the effect of these extreme conditions on fusion materials.

Our latest news on these expertises

21 September '23

21 September '23 31 March '23

31 March '23 23 March '23

23 March '23

More news on nuclear safety?