Lead-cooled Fast Reactor in Belgium

Demonstration model of innovative SMR-LFR

SCK CEN has been researching reactor concepts of the future for many years already. Recently it also started researching an advanced Small Modular Reactor (SMR), a Lead-cooled Fast Reactor or SMR-LFR. Cooled by lead, they could become an indispensable link in a sustainable energy supply.

Together with a robust, international consortium, we want to build a Belgian demonstration model of the very first lead-cooled Small Modular Reactor by 2035.

Advanced lead-cooled SMR:

a new generation of nuclear technology

Together with our collaboration partners, we are committed to developing an innovative and advanced fourth-generation SMR. A lead-cooled fast reactor or SMR-LFR. At the request of the Belgian government, we develop new technologies as a means of enabling the more sustainable implementation of nuclear energy and seek to respond to the concerns that exist within society. These could include reducing waste, increasing safety and using resources more efficiently.

What is a fast reactor?

In fast reactors, the chain reaction is maintained by fast neutrons.

To keep the neutrons fast, the reactor core cannot be cooled with water. Indeed, light molecules, such as water, inhibit neutrons. Heavy molecules such as sodium and lead-bismuth are eligible coolants, however.

The consortium opted for an SMR, in which lead is the coolant.

Lead-bismuth is also theoretically an option, but bismuth is too rare for the technology to be expanded to produce a fleet of SMRs.

Why a fast SMR?

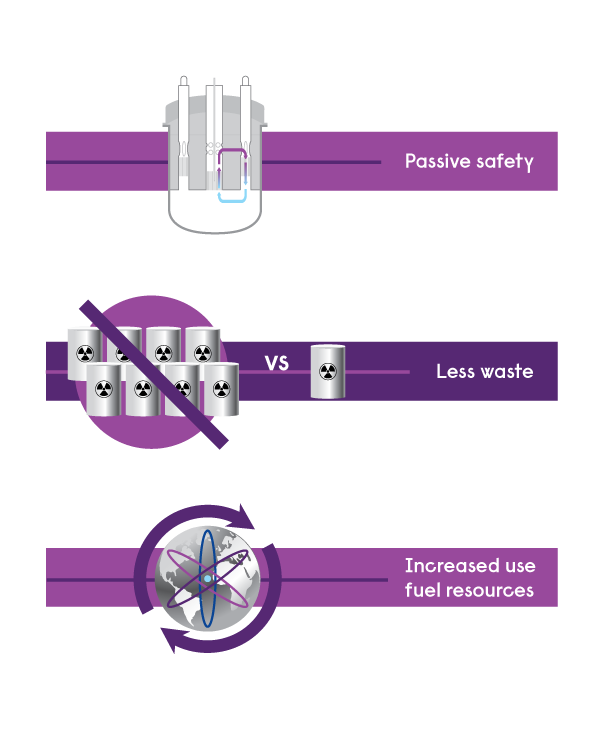

This advanced technology offers a number of benefits, especially in terms of sustainability and safety.

Safety

The design developed by SCK CEN focuses on passive safety systems. When the reactor shuts down, the coolant automatically dissipates the heat through natural circulation. An additional passive safety feature when using lead as a coolant in an SMR-LFR is that the reactor is not pressurised and therefore no pressure loss incidents can happen.

Less high-level radioactive waste & more efficient use of raw materials

In a closed fuel cycle, an SMR-LFR offers a number of advantages in relation to traditional, water-cooled reactors.

Compared to thermal neutrons, fast neutrons have a higher probability of also fissioning heavy elements (plutonium and ‘minor actinides’). Moreover, the energy efficiency is much higher because more uranium-238 is ultimately used (after neutron capture and fission of Pu-239) than in water-cooled reactors. A fast reactor can utilise the uranium feedstock more efficiently and can extract more energy from the same amount of available fissile material.

Since it operates in the fast neutron spectrum, an SMR-LFR also offers the potential to reuse fissile material that has already completed one cycle in a reactor and would normally be considered waste. This recycling allows spent fissile material to be put to good use again, thereby reducing the volume and radiotoxicity of the radioactive waste.

♻️ Want to know more about recycling fissile material?

An ironclad consortium for a forward-looking project

In November 2023, in the presence of Alexander De Croo, the Prime Minister of Belgium, Klaus Iohannis, the President of Romania, and representatives of the Italian and American embassies in Belgium, a Memorandum of Understanding was signed between five international heavyweights in connection with nuclear technologies that make use of heavy, liquid metals. Since then, the new consortium has been working together to enable the roll-out of these innovative SMRs.

Ansaldo Nucleare, ENEA, RATEN, SCK CEN and Westinghouse Electric Company will jointly fulfill all requirements for the successful implementation of lead-cooled small modular reactors as a low-carbon sustainable and competitive source in a future energy mix by providing a combination of electricity, heat and hydrogen production.

Belgian and Romanian precursors of a commercial SMR

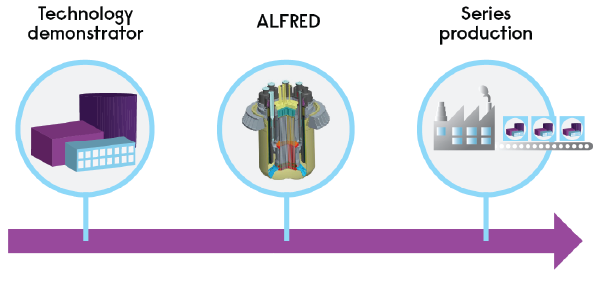

The commercial rollout will require extensive research and intensive testing. The newly formed collaboration has outlined a clear vision, based on a step-wise approach to demonstration. Together, we will fulfill all requirements for the successful implementation

1. Small-size reactor in Mol

It start with a small-size reactor in Mol, Belgium. By 2035, the Belgian demonstration model of the first-ever lead-cooled Small Modular Reactor should be ready. With that reactor, the partners aim to demonstrate its technological and engineering aspects.

2. ALFRED

A step toward the next development phase, which is the construction of ALFRED in Pitești, Romania, focusing on the technical and economic feasibility of future commercial SMRs. It will leverage and expand the work done in the past 10 years toward this objective by Ansaldo Nucleare, ENEA and RATEN under the FALCON consortium.

3. Commercialization

The Lead-cooled Fast Reactor design developed by Westinghouse will be the starting point for this project ultimately targeting its global commercialization, a commercial deployment of this technology with a time-to-market that remains as short as possible.

What is the Belgian budget spent on?

The government's mission and budget are focused on research and development. We want to build a demonstration model of this lead-cooled technology in Belgium in light of the industrial roll-out of SMR-LFRs. We cannot do this alone. We need input from other research organisations and industrial partners. We are merging our knowhow with existing knowledge and designs of partners, taking an immediate lead in the project.

The ultimate goal is to bring lead-cooled SMRs to the market, thus providing society with a sustainable energy solution. Of course, every partner, and by extension Belgium, wants to reap the benefits of this final solution.

The need for a contract between the different partners thus arises, with a clear description of both the input and the eventual revenues. Currently, only a "non-binding" Memorandum of Understanding has been established for the consortium. We want to convert it into a document that is binding before the end of the year.